DTF Printing Change: Releasing Creativity in Fabric Design and Manufacturing

DTF Printing Change: Releasing Creativity in Fabric Design and Manufacturing

Blog Article

From Principle to Development: Unleashing Creativity With DTF Printing on Various Fabrics

In today's dynamic world of textile layout, the usage of Straight to Film (DTF) printing modern technology has actually revolutionized the process of moving complex layouts onto various textiles. The fusion of innovation and virtuosity through DTF printing opens up doors to a realm where creativity understands no bounds.

Checking Out the Conveniences of DTF Printing

Why is DTF printing significantly preferred over other techniques for its adaptability and durability in the fabrics market? Direct-to-film (DTF) printing has actually been obtaining grip in the fabrics market due to its countless advantages that satisfy the developing needs of the market. One essential benefit of DTF printing is its flexibility in regards to the materials it can be related to. Unlike some standard approaches that are restricted to details fabric kinds, DTF printing can be used on a variety of materials, including cotton, polyester, blends, and also leather. This flexibility enables for higher creativity and advancement in fabric layout.

Furthermore, DTF printing uses phenomenal toughness, making it suitable for producing long-lasting styles on materials - DTF Printing. The prints created via DTF are understood for their dynamic colors and resistance to fading, breaking, or peeling - ensuring that the final item preserves its high quality also after multiple cleans or prolonged use. This longevity makes DTF publishing a cost-efficient remedy for producers seeking to produce top notch, enduring layouts on textiles

Creating With DTF: Tips and Tricks

Designing properly with DTF printing entails understanding the intricacies of electronic design software and understanding how to optimize styles for the very best outcomes on different materials. When producing layouts for DTF printing, it is essential to take into consideration the material texture, kind, and color to make certain that the end product fulfills assumptions. Here are some ideas and techniques to boost your DTF style process:

Resolution is Secret: Start with high-resolution images to preserve clearness and intensity in your layouts. Low-resolution images can cause a pixelated final product.

Shade Matching: Pay attention to shade accuracy when creating for DTF printing. Usage color administration devices to make certain that the colors in your layout translate properly onto the textile.

Vector Graphics: Utilize vector graphics anywhere possible to maintain the quality of your styles when scaling them to different sizes. (DTF Printing)

Test Prints: Constantly conduct test prints on example fabrics to examine the shades, resolution, and total style high quality before full-scale production.

Choosing the Right Fabrics for DTF

When considering the ideal textiles for DTF printing, the choice of material plays an important function in attaining the preferred top quality and durability of the last published styles. Fabrics with a high polyester web content are typically favored for DTF printing due to their capability to hold the ink well and produce brilliant prints. By carefully selecting the right textile for DTF printing, makers can enhance the durability and aesthetic influence of their layouts.

Step-by-Step DTF Printing Refine

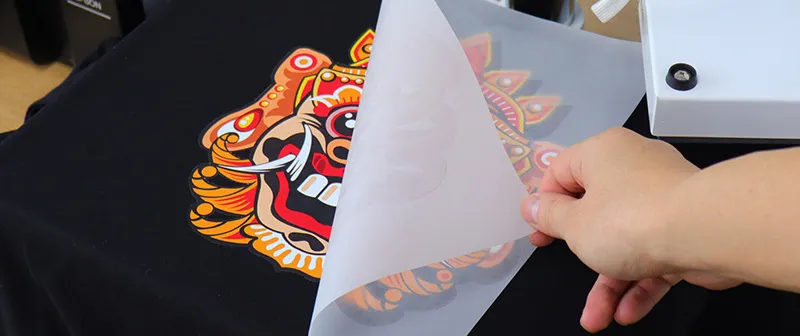

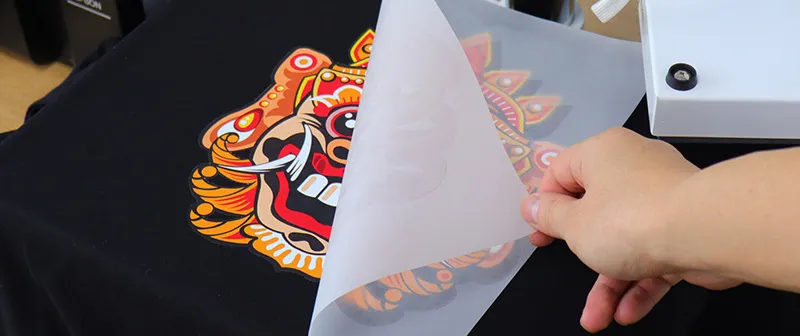

After healing, the printed design is after that transferred onto the fabric making use of a warmth press. The transfer process needs cautious placement to make sure that the design is used properly. As soon as the transfer is complete, the fabric is permitted to cool down prior to the transfer movie is peeled, leaving the vivid and long lasting design on the fabric. Ultimately, the textile might undergo post-processing therapies to enhance the layout's longevity and vibrancy, resulting in a high-quality final product ready for usage or display screen.

Showcasing DTF Masterpieces

Have you ever before marveled at the elaborate details and dynamic colors of DTF masterpieces showcased on different fabrics? DTF printing has actually transformed the method layouts are moved onto textiles, allowing click here now for exceptional accuracy and richness in colors. When these DTF masterpieces are placed on display, they mesmerize audiences with their striking visuals and thorough craftsmanship.

Among one of the most fascinating elements of showcasing DTF masterpieces is the convenience it offers. Whether recommended you read it's a attractive and strong design on a tee, an in-depth pattern on a pillowcase, or a customized print on a canvas bag, DTF printing allows for endless opportunities. This convenience allows designers and artists to unleash their creative thinking and bring their visions to life on a vast array of fabrics.

Moreover, the longevity of DTF prints makes sure that these work of arts can hold up against the examination of time without shedding their vibrancy. Whether displayed in galleries, used as fashionable garments, or made use of as decorative accents in homes, DTF masterpieces remain to thrill visitors with their remarkable high quality and visual appeal.

Verdict

Finally, DTF printing offers a innovative and flexible approach for unleashing creativity on various fabrics. By discovering the benefits of DTF printing, designing with specific ideas and tricks, selecting proper textiles, and complying with a step-by-step printing procedure, artists can showcase their work of arts effortlessly. This process enables the smooth transition from principle to creation, providing unlimited opportunities for innovative expression.

In today's dynamic world of fabric style, the usage of Direct to Movie (DTF) printing modern technology has changed the process of transferring complex designs onto various textiles.Creating successfully with DTF printing involves grasping the complexities of digital style software application and comprehending how to enhance styles for the ideal outcomes on numerous textiles.When considering the ideal textiles for DTF printing, the option of product plays a vital role in achieving the desired high quality and resilience of the last published designs. The next step is publishing the design onto a special DTF transfer film making use of a go to my site DTF printer with the appropriate ink. By exploring the benefits of DTF printing, designing with certain suggestions and methods, picking proper fabrics, and complying with a step-by-step printing procedure, artists can showcase their masterpieces with convenience.

Report this page